Copper beryllium wrought alloy msds march 3 2003 page 2 of 12 3 2 potential health effects exposure to the elements listed in section 2 by inhalation ingestion and skin contact can occur when melting.

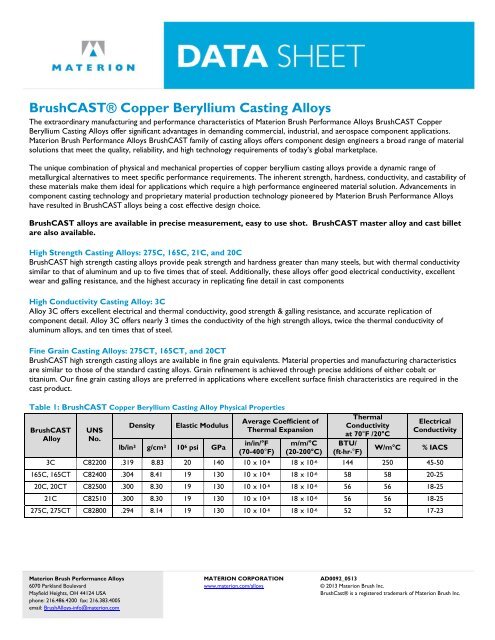

Beryllium copper data sheet.

Cda 172 beryllium copper is commonly used due to it s high strength and hardness compared to other commercial copper alloys.

Beryllium copper is non sparking but physically tough and nonmagnetic fulfilling the requirements of atex directive for.

4977 is known for allowing excellent detail in your casting combined with high strength and an attractive color.

This website is dedicated to providing employers and their associates with important information on working safely with beryllium containing materials.

Ams 4533 cda 172.

Alloy beryllium nickel cobalt nickel cobalt iron copper c17200 1 80 2 00 0 2 min.

Beryllium copper commonly referred to as becu and alloy 25 exhibits superb electrical and thermal conductivity.

Beryllium copper is a non ferrous alloy used in springs spring wire load cells and other parts that must retain their shape under repeated stress and strain it has high electrical conductivity and is used in low current contacts for batteries and electrical connectors.

Plastic process equipment inc.

Emergency assistance chemical family beryllium.

10 c17500 10zr c17500 14 c17510 25 c17200 165 c17000 717 c71700 supplier manufacturer.

Safety data sheet.

Product and company identification.

Copper beryllium wrought alloys.

Elmore ohio 43416.

8303 corporate park dr.

Our beryllium copper meets astm b194 specifications and is ideal for an array of applications.

To achieve it s high strengths whilst.

It is extremely ductile and as such can be stamped into complex shapes with tight tolerances.

Beryllium copper product specifications.

Beryllium copper alloy 20c cda 825 is our most popular offering in this category and contains 2 beryllium 0 5 cobalt and 0 25 silicon.

Cda 172 strength and hardness is similar to that of steel.

Material safety data sheet no.

Other means of b200.

Beryllium copper alloy sheet foil rod wire.

20c beryllium copper belmont product code.

Beryllium safety for over 80 years we have been at the forefront of developing and implementing comprehensive health and safety procedures and techniques related to occupational beryllium exposure.

Balance physical properties elastic modulus melting point solidus electrical conductivity resistivity density thermal expansion coefficient thermal conductivity 25 c 19 000 ksi 131 gpa 1600 f 870 c 22 28 iacs 6 2 7 8 μωcm.

1 product and supplier identification.